In physical gas adsorption, an inert gas, mostly nitrogen, is adsorbed on the surface of a solid material. This occurs on the outer surface and, in case of porous materials, also on the internal surface induced by pores. Most widely known is the determination of the BET surface area by gas adsorption, sometimes referred to as BET analysis. Adsorption of nitrogen at a temperature of liquid nitrogen, i.e. 77 K, leads to a so-called adsorption isotherm, or BET isotherm, which can be measured over porous and non- porous materials. Non-porous materials will display a type II isotherm on which the BET surface area can be determined. Porous materials will typically provide a type I or type IV isotherm, depending on the type of pores being present. BET analysis over type I isotherm materials requires a specific treatment in order to accurately assess the BET surface area. In specific cases, like for zeolites or activated carbons, the use of argon adsorption or carbon dioxide adsorption is often preferred over nitrogen adsorption to accurately probe the small micropores. Samples with low BET surface area can adequately be characterized via a BET analysis by krypton gas adsorption. In those cases, only a part of the isotherm can be measured, but this still provides a BET surface area with high accuracy.

BET analysis

The principle of monolayer formation of gas molecules on the solid surface is used to determine the specific surface area. The BET model employing a linearized BET equation is then used to transform the experimental adsorption isotherm into a BET plot and in this way the monolayer volume can be determined. In this BET analysis, the cross section area of the gas molecule together with the monolayer volume is then used to calculate the total specific surface area expressed in m2/g.

Besides BET analysis, gas adsorption can also be applied to assess the presence of pores, not only in terms of pore volume but also as a pore size distribution. The principle of capillary condensation in pores can be applied to determine the pore size distribution since the capillary condensation in pores is pore size dependent. A higher pressure is needed to induce condensation in larger pores. Likewise, smaller pores are filled at lower partial pressure of the adsorbing gas.

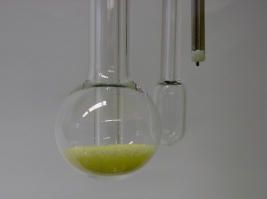

Prior to the measurement, the sample is pre-treated at elevated temperature in vacuum or flowing gas in order to remove any contaminants. It is crucial to tune the pre-treatment conditions to the materials properties as a too low or too high temperature can seriously affect the BET surface area derived from the subsequent BET analysis.

In general, two different techniques can be distinguished for the subsequent adsorption analysis:

>> The flow technique uses a TCD detector to obtain information on the amount of adsorbed gas resulting in a specific BET surface area and/or total pore volume.

>> The volumetric technique is based on pressure measurements in an enclosed volume and provides more information, since many adsorption and/or desorption points are measured providing a full isotherm with information on BET surface area, pore volume and pore size distribution.

The flow measurements can be performed on a Qsurf M3 analyzer and the report consists of a single value for the BET area or total pore volume. The volumetric adsorption measurements can be performed on a variety of instruments, such as Quantachrome Autosorb-6B (N2 or CO2), Micromeritics TriStar II 3020 (N2), Micromeritics Gemini or Micromeritics ASAP 2020 or Quantachrome Autosorb iQ (Ar or Kr) and the report can be a single value for the BET surface area up to a full report on isotherm, specific BET surface area, total pore volume and pore size distribution, thus going beyond a simple BET analysis.